3M Finished Goods Planning

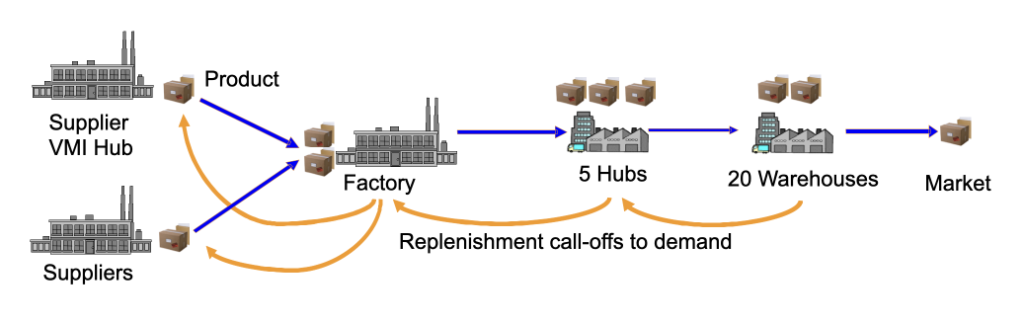

- Stocking locations in hubs and warehouses across Europe

- Planning done centrally

- Stock targets for each location based on volume and order patterns

- Local warehouse stock set by market demand, lead time to ship from hub & batch size to ship

- Hub stocks set by call off demand pattern, lead time & batch size to make in the factory

- Supplier stocks set against factory demand and lead time to resupply

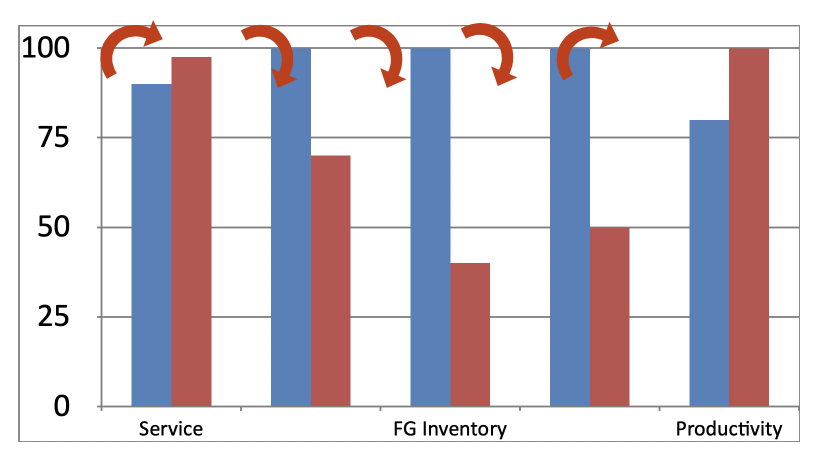

Results

- Stock held in 5 EDCs, 20 warehouses and inbound to the 3M factory

- 30% reduction in on-hand inbound inventory

- 60% reduction in FG inventory across all sites

- Service performance > than 97% target

- Elimination of process gaps in factory between Lean / Pull methods and planning approach

- Improved productivity and better communication & relationships across supply chain

Client Review

“Working with O8 has put us back in control of the supply chain.”

3M Supply Chain Manager, OH & ES, Europe