A.G. Barr Demand Driven Production Success

Production stability was the prime driver for adopting O8’s demand-driven supply planning at a major soft drinks manufacturer.

A.G. Barr managed to stabilise the production and reach 99%+ service level while reducing the inventory by 40% using O8’s software solution.

Very high service levels at supermarket chains are critical in the soft drinks industry.

Over- and under-stocking due to constant production re-prioritisation was a severe problem in not getting to over 99% service at A.G. Barr.

About the Project

A.G. Barr p.l.c. is a FTSE 250 UK based, branded consumer goods business focused on growth. The company was established over 140 years ago in Scotland.

A soft drinks business at its core, A.G. Barr offers a diverse and differentiated portfolio of great tasting brands such as the iconic IRN-BRU, market-leading RUBICON exotic fruit juice drinks, and the Scottish spring water STRATHMORE.

In 2017, supported by Scala Consultancy and O8, they started a managed path to Demand Driven production. Scala and O8 worked with Paul Comrie, Head of A.G. Barr’s Supply Chain Optimisation Team.

Strategic change was driven from the top. Andrew Memmott, Director of Supply Chain, set the goal to find a tool to kill instability and meet very high service levels.

Benefit Rapidly Achieved

Operational ease was soon seen. Michael Lynch, Supply Chain Performance Manager, noted ‘ease of use was impressive, within two weeks we were planning in 20 minutes what used to take two days’.

Stability on the trial production line – ‘C3’ – was soon gained. The Production Manager noted that the buffers of the Demand Driven approach had removed disruptive and inefficient product changes due to ‘wrong product, wrong inventory’ issues. (And, unexpectedly, freed up time to deal with the highlighted maintenance issues.)

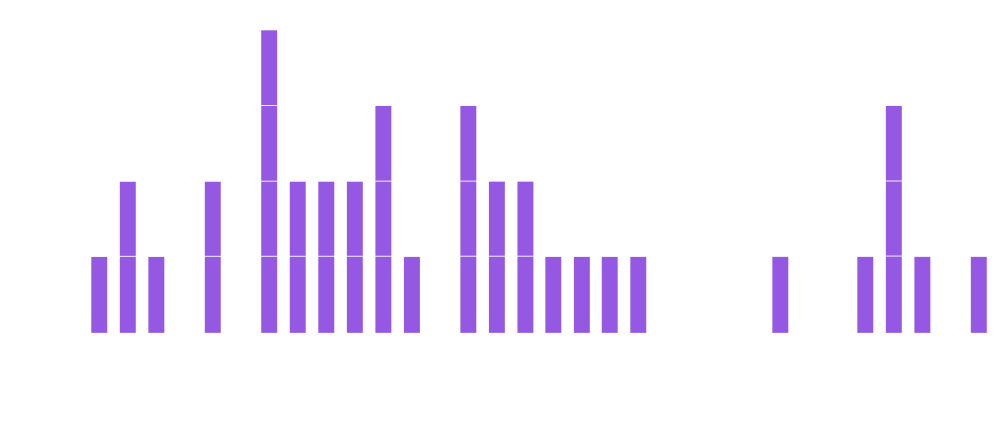

C3 LINE CHANGES PER WEEK

‘Wrong product, wrong inventory’ production issues were eliminated.

In 2018 a full switchover was made to fully integrate inventory levels, production scheduling and distribution to the flow mechanics of the Demand Driven Planning.

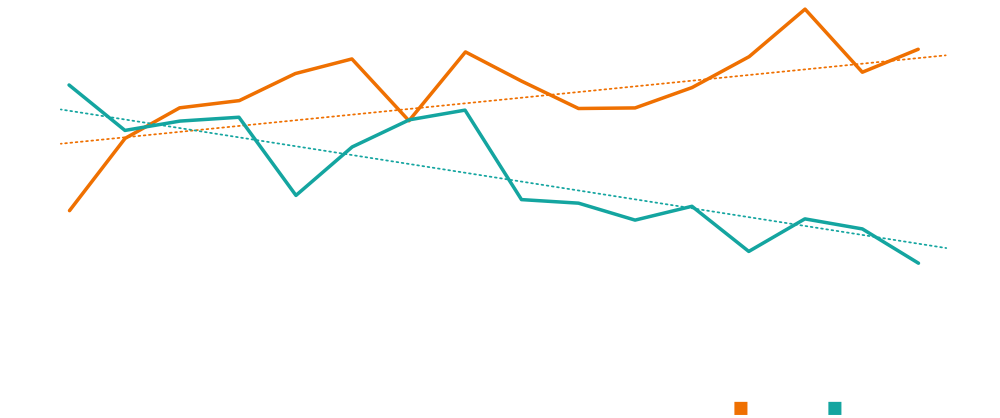

INVENTORY ALIGNED AND REDUCED

The reduction of inventory has continued, after the 2017 trial, operationally in 2018 with a year-on year, before and after adoption of DD Planning, fall over 40%.

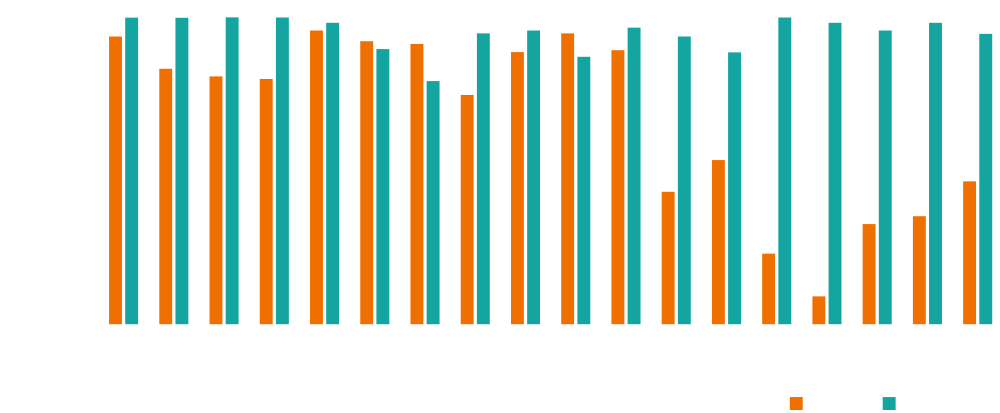

The critical service level – 99+% – was not only reached within 4 months but remained stable. The Demand Driven approach aligned inventory with demand, and production volumes aligned with replenishment need.

SERVICE LEVEL STABILITY

The O8 system is configured to support a target fill metric of 98.6%. The 2018 metric is 98.6%, compared to the pre-Demand Driven value of 93.7% of 2017 (week-to-week comparison).

And this is achieved with lowered inventory.

Success Recognised at the Board

This is a no-brainer – do it.

Paul Comrie prepared for a one-hour Board review of the business case to rollout across three production sites, two Distribution Centres and ten production lines.

It took just 5 minutes for the ‘Go’ decision to be made.

Success Seen in the Warehouse

Paul Comrie told a story to a weekly project meeting that captured ‘shop floor’ success:

Warehouse Manager:

‘We have much more space in our warehouse than last year. What is going wrong?’

Paul:

‘Have you failed in meeting any customer orders in the past two months?’

Warehouse Manager:

‘None at all’.

Paul:

‘We’re getting it right then. Nothing is wrong.’

What Did A.G. Barr Get Right?

- Clarity in getting a comprehensive solution that would completely replace MRP.

- Intensively utilising all product functions to work end-to-end, comprehensively switching to using buffered demand to plan, schedule, produce and distribute.

- Co-developing new functions such as ‘Shipment Builder’. This optimises transport efficiency and automatically moves product to where it is most needed.

- Change was driven from the top.

- Being bold in running a trial on a prime commercial line of business but using a phased approach to manage change.

Are you ready to take the next step?