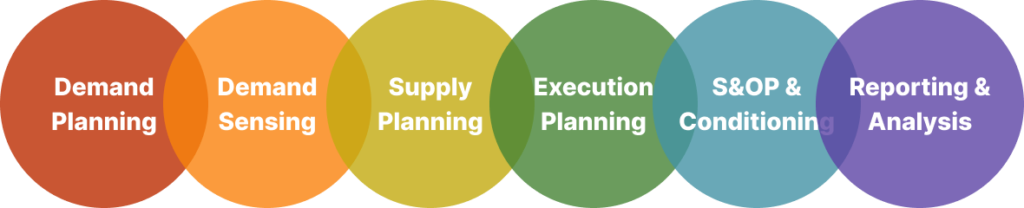

Solutions

○ Demand Planning ○ Supply Planning ○ S&OP

Demand Planning

- Hierarchies

- Outliers

- Transparent AI

- Event History Mining and ML

- Modelling

- Baseline/Promo/Seasonal/Event

- Market Intel/external data wrangling

- Financial

- Scenarios

- Up/downside

- Manual override

- PLM / NPI management

- Demand Hub (data sharing and integration)

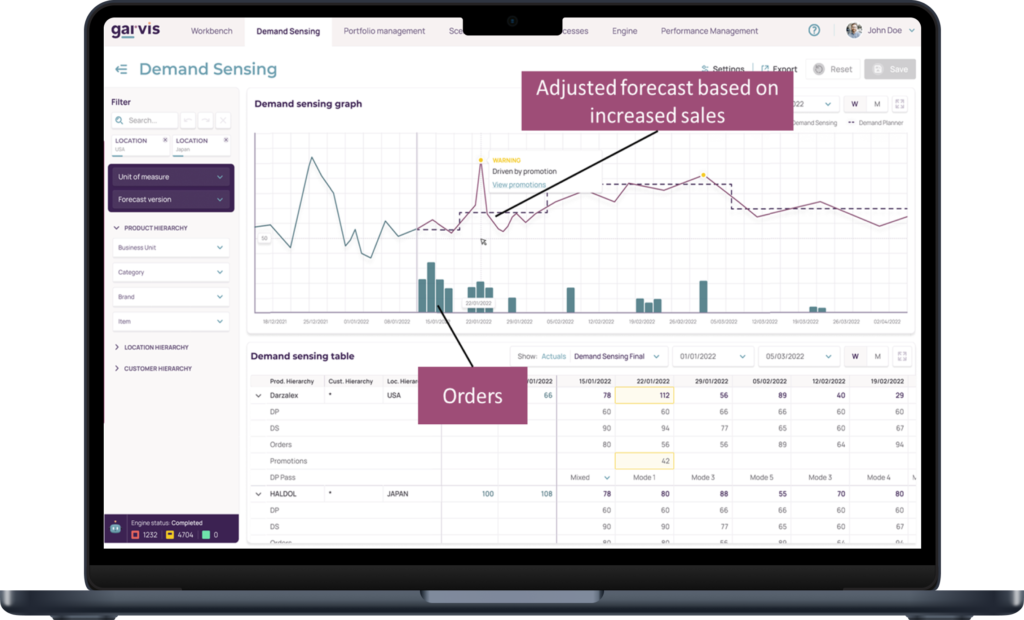

Powered by Garvis

Powered by Garvis

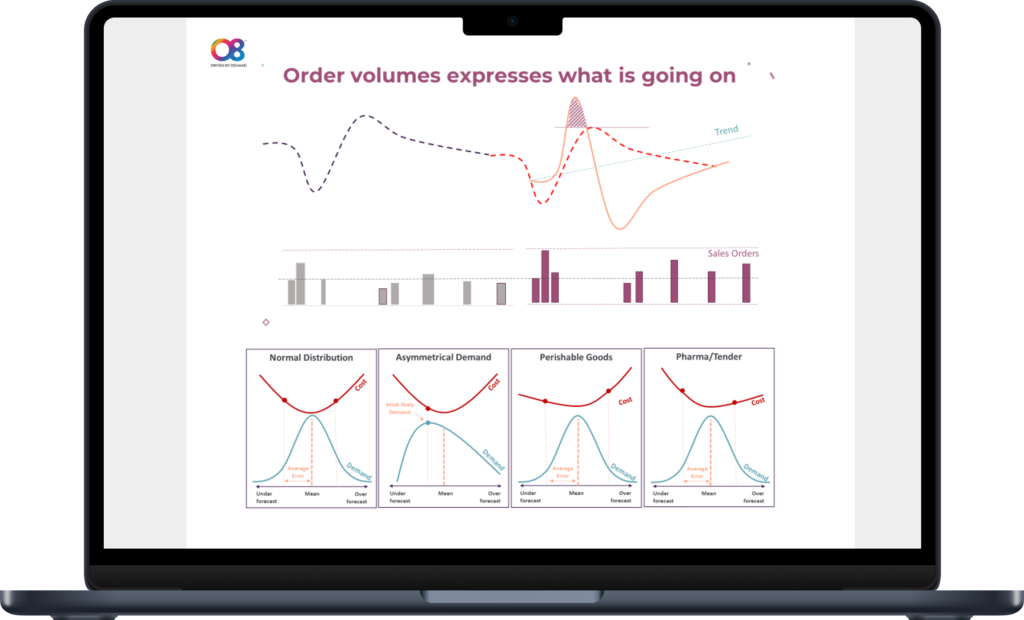

Demand Sensing

- Pattern recognition

- External data correlation

- Self learning/adjusting ML

- Advanced forecast consumption/fine tuning

- Direct linkage to Supply Planning for actionable insights

Supply Planning

- VVA segmentation, ABC

- Analysis

- Buffer calculation (inc actual variability)

- Replenishment order creation (auto and manual)

- Planning rules (by SKU/group/policy)

- DDMRP, ROP, ROC, MTO, Rate etc

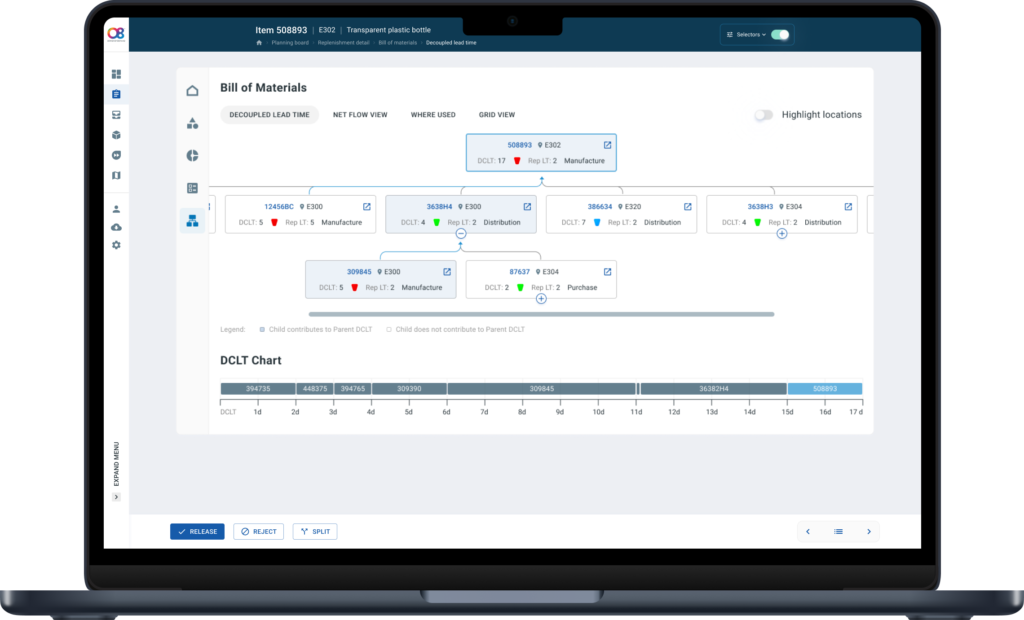

- DCLT calculation

- Forward Plan

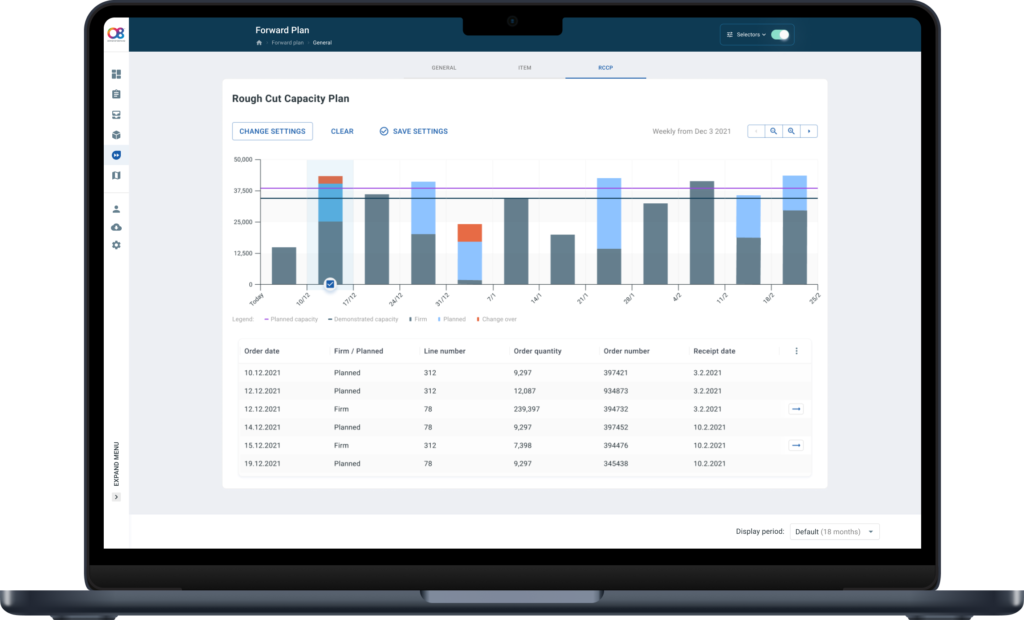

- Capacity (in any unit real or virtual)

- Tank capacity planning

Execution Planning

- Generation of new replenishment orders

- Material availability check

- Capacity check

- ATP

- Order Mngt and Prioritization

- Alerts (multi-level) including shortages and excess

- Order export/integration

- Via interface or email configuration

- Leadtime and date management

- Order grouping (aggregation/disaggregation)

S&OP & Conditioning

- Supply Order projections

- Med/Long-term capacity planning (any unit)

- Inventory projections (Multi-echelon)

- Finance projections (revenue, working cap etc)

- Buffer recalculation

- Auto segmentation & planning rule application

- Service level projections

- Tactical alignment to business strategy

- Demand Sensing integration

- Plan for each part

- Scenario modelling

Reporting & Analysis

- Extensive report library

- User-driven/self-service analytics

- LogiAnalytics

- Export

- Auto-Email

- Control Cockpit

- Process Compliance Metrics

- Business Warehouse data integration

- Bespoke Dashboards

“Orchestr8 has really brought value to our planning process. Delivering high levels of customer service whilst reducing inventory is the holy grail of any Planning Organisation – with O8 we have achieved this”

Case Study

British Telecom: Demand Driven with O8

• Supply chain ‘de-risked’ from forecast accuracy

• Overall inventory reduction between 20%-30%

• Maintained or improved service levels at 99%+

• Plan changes reduced to almost zero

• Strong positive impact on cash flow and ROCE

• Planning effort substantially reduced

• Initiated the change to a simple and robust DD S&OP process

Do you recognize these symptoms?

Our Mindful Planning Solutions will help you

Planner

• Day in the life of a planner is stressful

• Continuous changing priorities, excessive firefighting

• Standard planning tools do not support modern business requirements

Manager

• Incremental improvement

projects don’t last

• Planning and business processes are not aligned and are rarely reconcilable

• Crisis in talent development and retention

Leadership

• Persistent tension between inventory, service and cost

• Persistent failure of IT and

process investments to

deliver a ROI

• Difficulty to create real supply chain competitive advantage